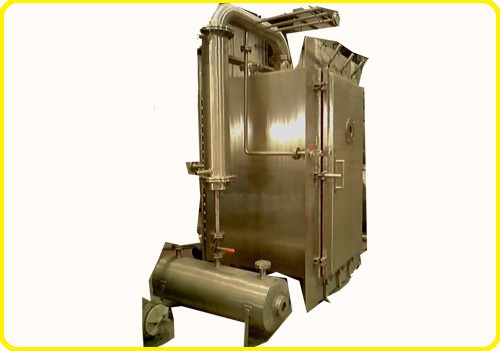

Tray Dryers (TD)

Tray dryer is an enclosed insulated chamber in which trays are placed on top of each other. Heat transfer is done by circulation of hot air by electric heaters or any other heating media. Blower fans are installed inside to ensure proper circulation and transfer of heat. These dryers are used for diverse applications such as Drying of Pigments, Food, Bakery, Electrodes, Chemical, Plastic, Powders etc.

Product Code : HETD-24 to 192

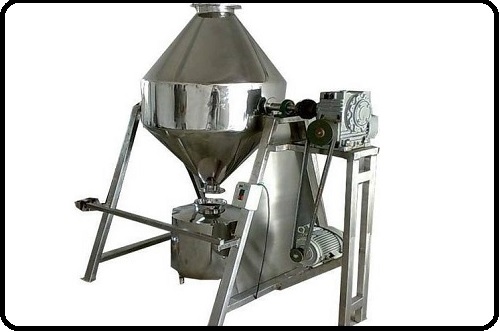

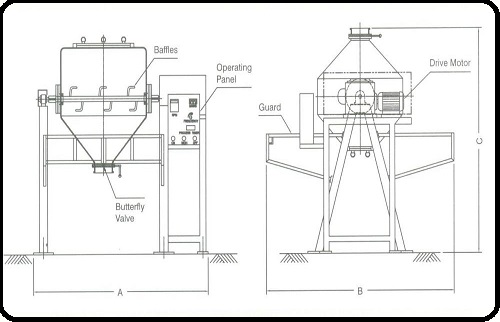

Double Cone Blenders

We are a prominent organization in this domain, actively engaged in offering a wide gamut of Double Cone Blender to our respected customer. The offered collections of the products are made from the finest quality raw material in accordance with the industry laid standards under the assistance of the skilled professionals.

Product Code : DCB

Features

- Application : Pharmaceutical, Food, Chemical and Cosmetic Products

- Material : SS304

- Finish Type : Matte Finish, Mirror Finish

- Capacity :10 to 1000 kg

- Model :GMP

Octagonal Blenders

In keeping with our theme of client satisfaction, we are offering Octagonal Blender. Octagonal Blender is considered to be high effective blending machine. It could efficiently mix dry granules and apply lubrication process with ease. This Octagonal Blender is proven for its reliable performance. Owing to its octagonal shape, it could easily process large volume of material in comparison to V and double coned blenders.

Product Code : OB

Features

- Material : Stainless Steel 304 / 316 and 316

- Capacity : 25 Ltrs to 5000 Ltrs

- Usage : Industrial

Ribbon blenders

Our organization is actively devoted towards offering a wide gamut of Ribbon Blenders. The offered range is manufactured by our dexterous professionals using high grade raw material and advanced technology. Owing to their indispensable features, these industrial blenders are widely demanded by our clients. Apart from this, we offer our clients a superior range of machines that require minimum maintenance.

Product Code : RB

Features

- Design Type: Customized, Standard

- Material: Ss, Stainless Steel, Mild Steel, Ms

- Capacity: 200 To 3000 Kg Per Batch

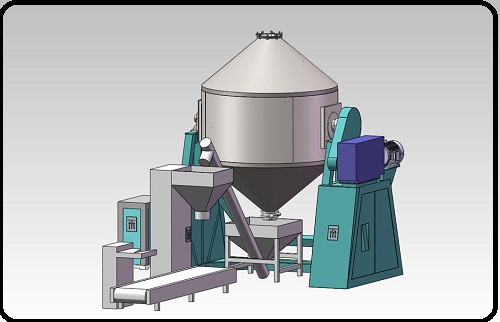

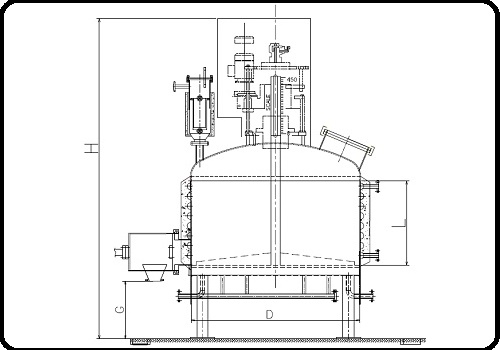

Roto Cone Vacuum Dryers(RCVD)

Roto Cone Vacuum Dryer suitable for drying of materials which cannot resist high temperature, material which are easily oxidized, volatatile materials which should be retrieved, materials strong irritant and poisonous in nature. The roto cone dryer with improved technology integrates during operation under vacuum. The roto cone dryer facilitates enhanced drying efficiency, low temperature operation and economy of process by total solvent recovery. It helps cGMP based working by achieving optimum dust control, while offering advantages of efficient charging and discharging of materials. The drying unit equipped with lump breakers initially breaks large lumps and subsequently powders them (in single cone). The rotary action of the dryer together with mechanical action of the breakers cuts down drying time and gives a lump free product.

Product Code : RCVD

Features

- Reduces drying time

- Eliminates need for re-drying of lumps

- Handling and exposure of final product is avoided

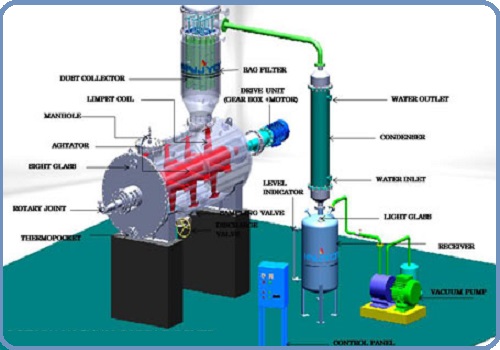

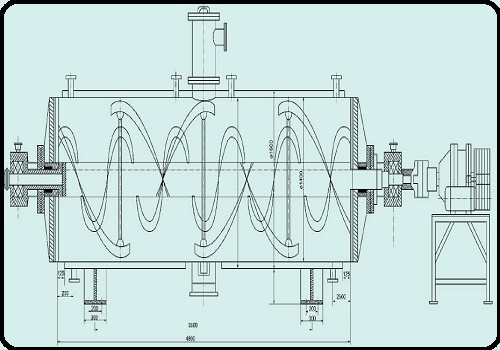

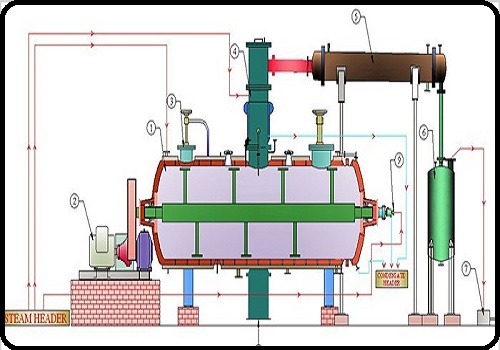

Rotary Vacuum Paddle Dryers (RVPD)

Rotary vacuum paddle Dryer or Paddle Dryer is used to obtain dry Powder from wet cake or solutions. The efficiency is very high and the operating costs are low compared to other types of dryers. It is a closed system in which hot water ,steam, or hot fluid is used as a heating medium in the jacket, in the hollow paddle and in the hallow shaft.

Product Code : RVPD

Features

- Common base frame is unique to this system.

- Drying optimization, this is done by means of external and internal heating.

- Mechanical seals at Shell ends/Stuffing Box.

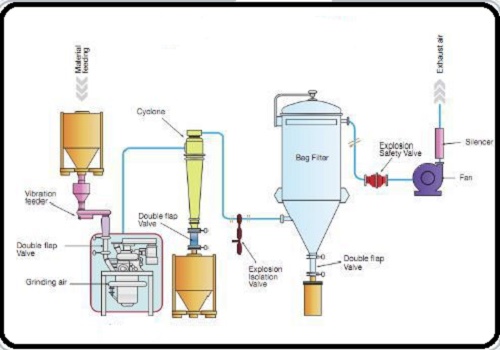

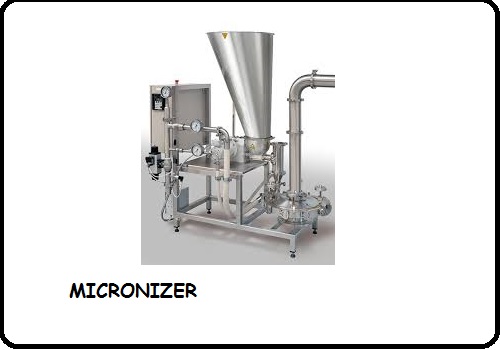

Multimill

Multi Mill can be used widely for wet & dry granulation, pulverization etc. in various type of applications, such as Pharmaceutical, Cosmetic, Dyes, Colours, Food Products, Spices, Detergents, Insecticides, Plastics & Resins, Fertilizers etc. This portable, self-contained unit is useful for high-speed granulation, pulverizing and mixing of a wide range of wet and dry materials effectively.

Product Code : Multimil

Features

- Automatic Grade : Automatic, Semi-Automatic

- Design : Standard, Customized

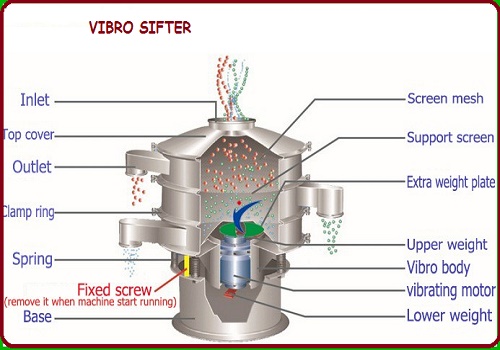

Vibro Sifter

Vibro Shifter is a set of extremely effective circulatory screening machines, which is used for testing of shades or fluids in a number of sectors. These products are useful in rating of content according to their compound size and are used splitting huge structure of solid and fluid. This ranger is set up with exclusively engineered engine, which is set up top to bottom at the center of the platform dish of the display. The display is fixed between the providing hopper and the package.

Product Code : HRS

Features

- Automation Grade : Automatic

- Power Source : Electric

- Voltage : 220 V

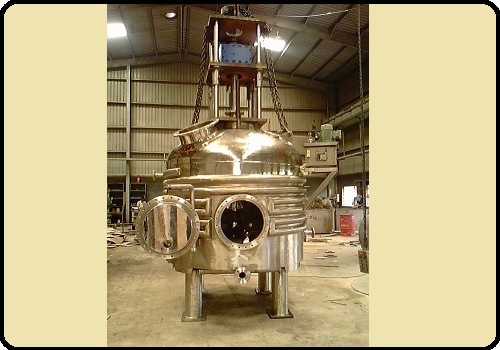

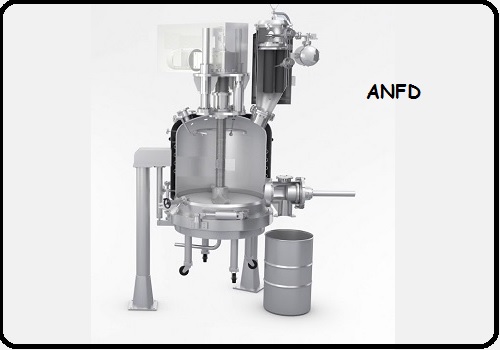

Agitated Nutsche Filter Dryer (ANFD)

Agitated Filter is a closed vessel designed to separate solid and liquid by filtration under pressure or vacuum. The closed operation ensures odorless, contamination free and nonpolluting working conditions maintaining product purity and hygiene. The advanced technology of agitation and hydraulics used in the equipment makes it versatile and user friendly. The resulting wet cake can be reslurried and washed thoroughly with water or solvents unlike in” NUTSCHE” type filters or centrifuges. Wash liquid quantity can be controlled and recycled, reducing effluent load.

Product Code : ANFD

Features

- Discharge valve operation for labour – free cake removal.

- Lowering and lifting the Agitator.

- Lowering the detachable bottom when provided.